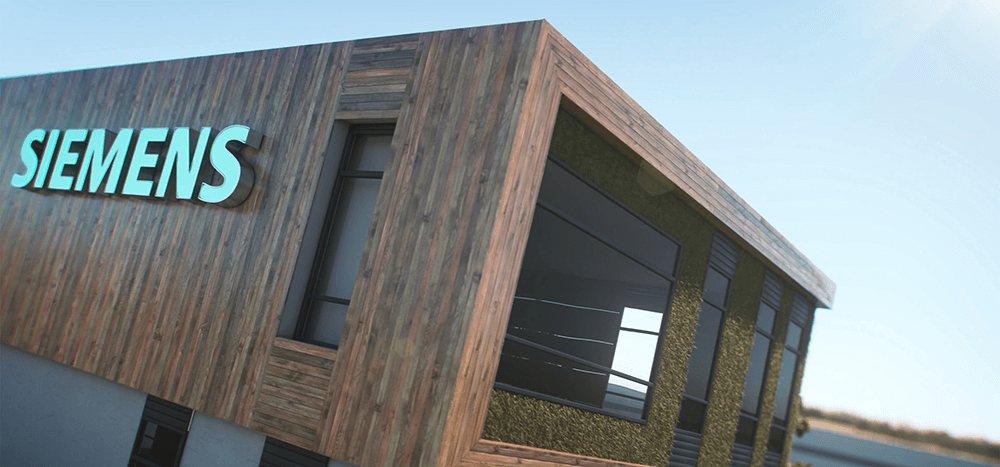

3D Visualisation

The long story short

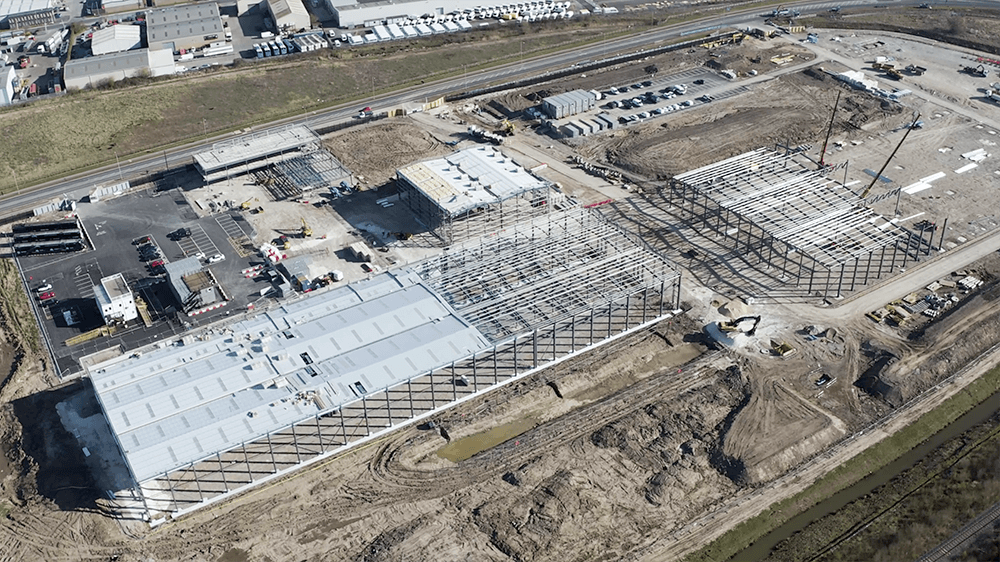

Siemens Mobility needed an effective way to help visualise their new £200m rail facility in Goole and track the progress they were making with the build. We created them a fully-immersive 3D environment, enabling visitors to visualise and explore the facility three years before it opens. We also captured monthly drone footage to create a video diary of their build progress.

Siemens Mobility

The Brief

Siemens wanted to bring to life their new, state of the art rail development in Goole. The problem was that there were only architects plans and a big empty field that didn’t give the most inspiring vision.

The development is huge for Siemens Mobility and for the local region. Evidence of progress being made needed to be captured as well as sharing the vision for the future.

The Solution

Working closely with the architects, we created a 3D model of the train facility. The giant buildings were replicated down to the finest details, such as the living roof on the site office.

Using this model, initially we created an animation showing the building growing from the ground – highlighting the vision for the future.

The 3D models were then used in an augmented reality view of the site. Here, visitors to the rail facility can see where buildings will be placed and experience the scale of the development by using augmented reality to view the set up through their phone or tablet.

Finally, helping Siemens plan the interior of their warehouses, we created a digital environment where they can plan the layout of equipment, demo how products will transition through the production process and showcase progress to date by give links to footage like the evolving drone ‘hyperlapse’ footage.

The Outcome

Visitors to the Siemens Mobility site can view the whole area at true scale through a smartphone or a tablet and see how it will look in future.

The technology enables you to switch between the different phases of the development and, because it is linked to GPS, wherever you’re standing on the site, you can see all the buildings related to that specific area.

It gives perspective and scale of the buildings and helps Siemens Mobility to make changes as the project moves forward.

Siemens can open the doors to their innovation early, by inviting press and guests to explore the facility through the digital model and warehouse set up processes are being streamlined by being able to test configurations before committing to a build.

We have been working with Clay10 on our Goole project now for over 12 months. Their passion & commitment to their craft is authentic and inspirational.

Their ability to reimagine old problems and come up with ultra modern digital solutions, in very quick time, is a real asset to what we are doing at Goole.

The biggest compliment is that they make us more productive, by enabling us to work smarter. And being more productive is what it's all about in industry.

Finbarr Dowling,

Siemens